As with all transport vehicles the structure is built on a frame. In the case of a car the body is placed on the chases. Similarly, aircraft have a frame around which the rest of the machinery is installed. The frame needs special care as at the height and the speed at which aircraft travels even a scratch could cause a crash…….

Depending on the aircraft type, airframe heavy structural inspections are scheduled every 6-12 years. Usually the aircraft is taken out of service for several weeks. During this check the exterior paint is often stripped and large parts of the outer paneling are removed, uncovering the airframe, supporting structure & wings for zonal and structural inspections. In addition many of the aircraft’s internal components are functionally checked, repaired/overhauled, or exchanged. The MPD document provides maintenance planning information necessary for operators to develop a customized maintenance program. The document lists all recommended scheduled maintenance tasks for every aircraft configuration. Scheduled maintenance tasks are categorized into three program groupings consisting of: a.) Systems & Powerplant, b.) Zonal Inspections, and c.) Structural Inspections

a) The Systems & Powerplant Program is developed to perform functional and operational checks on typical airplane systems i.e. flight controls, pneumatics, electrical power, etc.

b) The purpose of the Zonal Inspection Program is to assess the general condition of attachment of all systems and structures items contained in each zone by use of defined zonal inspection tasks. The zonal inspection tasks include visual checks of electrical wiring, hydraulic tubing, water/waste plumbing, pneumatic ducting, components, fittings, brackets, etc.

c) The Structural Inspection Program is designed to provide timely detection and repair of structural damage during commercial operations. Detection of corrosion, stress corrosion, minor damage and fatigue cracking by visual and/or NDT procedures are considered.

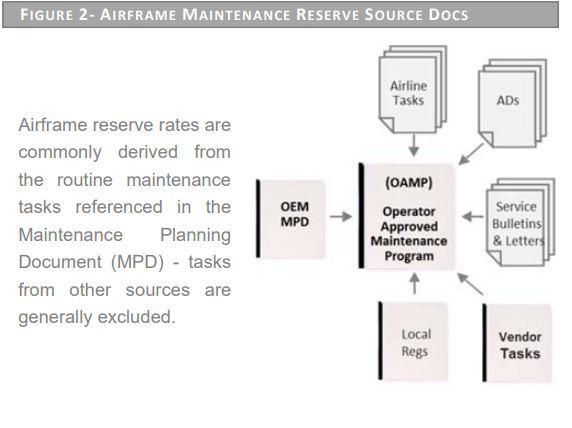

It is the MPD that outlines the task requirements used to assess airframe maintenance reserves. In general, the MPD routine maintenance tasks, and the rectification of any deficiencies resulting from performance of such tasks, forms the basis for the qualifying scope of work that is used to quantify airframe maintenance reserves. The lessor, thus must factor incremental costs resulting from non-routine maintenance into the airframe rate.

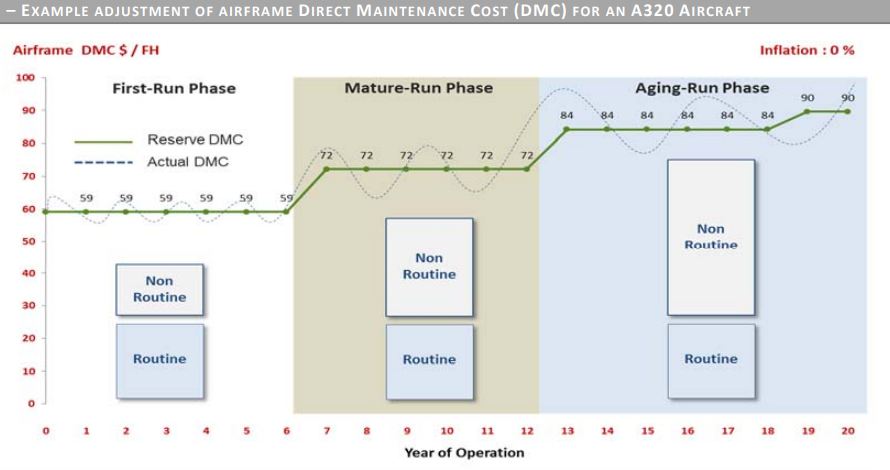

Maintenance Cost Drivers Aging of aircraft – As an aircraft ages subsequent airframe heavy checks are expected to require higher levels of non-routine maintenance, which is defined to be the work required to rectify routine maintenance tasks. The non-routine ratio – sometimes referred to as the defect ratio – is the ratio of non-routine manhours to routine man-hours, and is a measurement of the incremental time required to correct routine defects. For example, if an aircraft’s heavy structural inspection requires 4,000 routine man-hours, in addition to 2,000 non-routine man-hours, the non-routine ratio for this check is 50%. As an aircraft ages, the non-routine ratio can easily exceed 100%, which explains why successive maintenance checks tend to be more costly. Therefore, when developing airframe maintenance reserves it’s important to adjust the rate to account for the particular phase within the airframe’s maintenance cycle. The airframe’s maintenance cycle can be broken into three phases consisting of: first-run, maturerun, and aging-run. Figure 3 highlights the changes in airframe Direct Maintenance Cost (DMC) of an A320 aircraft as it progresses through its maintenance cycle.

• First-Run is the initial operating years, often referred to as the honeymoon period and generally considered the first 4-6 years of in-service operation. The structure, systems, and components are new; and there is less non-routine maintenance and material scrap rate.

• Mature-Run begins after the newness phase and runs through the first maintenance cycle. This period typically falls between the first heavy maintenance visit and the second maintenance visit.

• Aging-Run begins after the end of the first maintenance cycle when the effects of airframe age result in higher non-routine maintenance costs. This period typically begins after the second heavy maintenance visit and continues to increase with time.

Typical Qualifying Work : Man-hours associated with scheduled grouping of MPD routine tasks and all non-routine man-hours generated by routine tasks, material costs related to the above tasks, basic cabin refurbishment, and rotable overhaul for time-controlled items. Some lessors include strip & paint into their standard reserves if these events occur at regularly scheduled heavy structural checks.

Typical Excluded Work : Work related to Service Bulletins (SBs), Service Letters (SLs), Airworthiness Directives (ADs), airline unique tasks, vendor tasks, local regulatory tasks, cabin reconfiguration costs, accidental damage repair. Packaging, duties, and shipping & handling fees are also generally excluded. Some lessors exclude tasks associated with the Systems Maintenance Program.

Example Airframe Reserve Estimations

A. Airframe Heavy Structural Event : A320 C4 / 6-Year SI & C8 / 12-Year SI

B. Inclusions: The labor and material cost of performing all MPD tasks affiliated with the Systems, Structural, and Zonal Maintenance Programs, and the rectification of any deficiencies resulting from performance of such tasks, stripping and painting, cost of cabin refurbishment and rotable overhaul costs for time-controlled items.

C. Exclusions: Work related to Service Bulletins (SBs), Service Letters (SLs), Airworthiness Directives (ADs), airline tasks, vendor tasks, local regulatory tasks, cabin reconfiguration, accidental damage repair. Packaging, duties, and shipping & handling fees are also excluded.